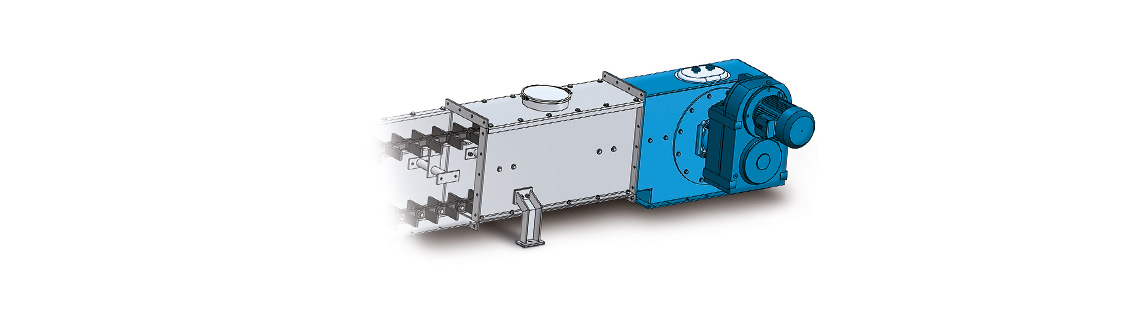

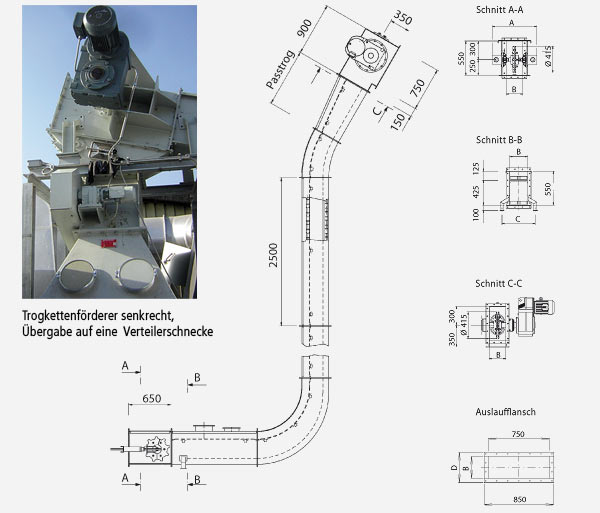

Trough Chain Conveyor Vertical

SCHRAGE vertical trough chain conveyors are, as with the horizontal trough chain conveyors, built according to the construction module principle. They only differ with regard to the trough design. A false floor is installed in the inlet area to prevent overflowing.

As a result, the product is transported evenly in the in winding compartment. The entire vertical conveying side is also equipped with a false floor so that the bulk is forced through in a continuous flow.

Technical Structure

Main dimensions

Theoretical capacity

with bulk height in trough at 125 mm

Structure

- Driving unit

With shaft-mounted geared motor or geared motor with chain drive - Tensioning unit

Gravity or spring tension - Conveyor trough

Made of chamfered metal plate, removable cover with inspection opening - Conveyor chain

Single chain or multiple chains, according to size - Monitoring

- Motor load monitor,

- speed sensor,

- torque monitoring

- tension path monitoring, etc.

Designs

- dustproof and product sealed

- waterproof

- gastight

- design in accordance with Atex

(dust explosion classes) - external / Inside bearings

- drop-forged conveyor chain

- sprockets with replaceable segments

- wear rails

- special constructions upon request