Products / Screw Conveyors / Trough and tube screw conveyors

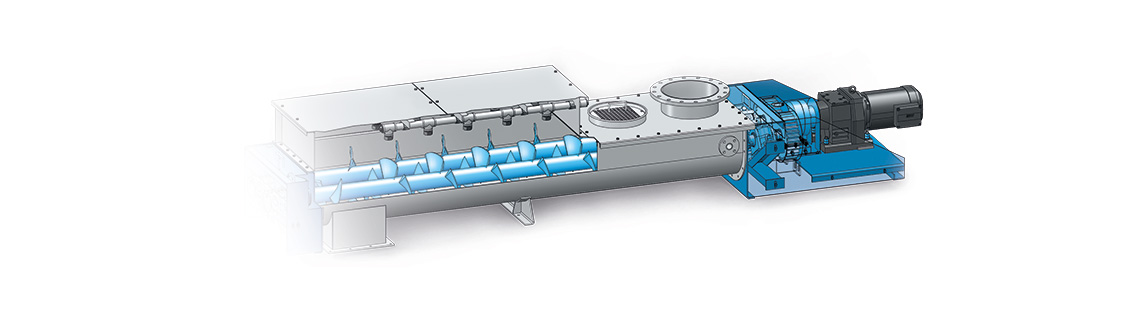

Trough and tube screw conveyors

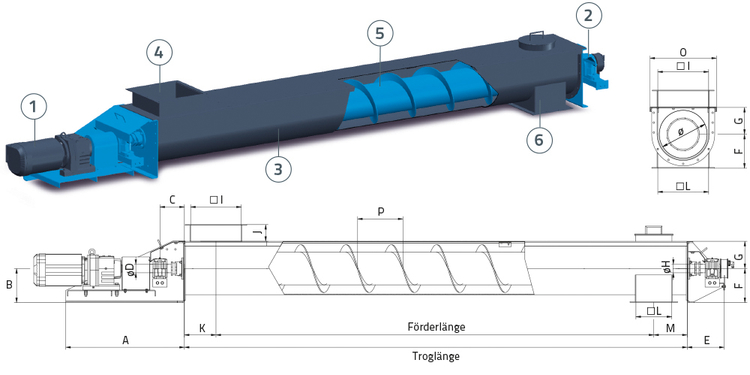

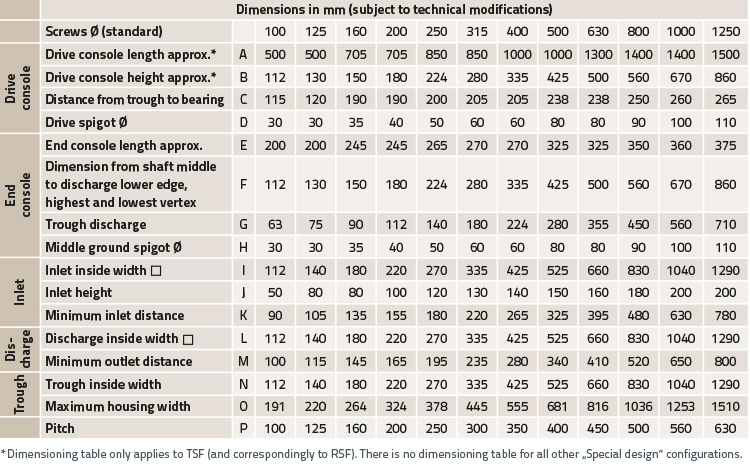

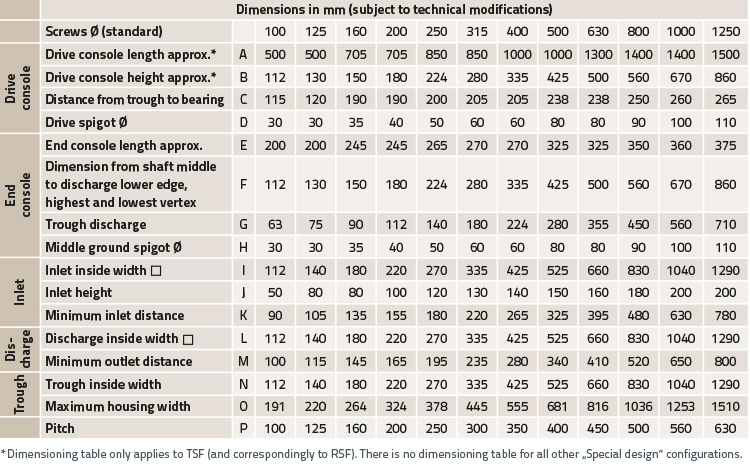

Design Data*

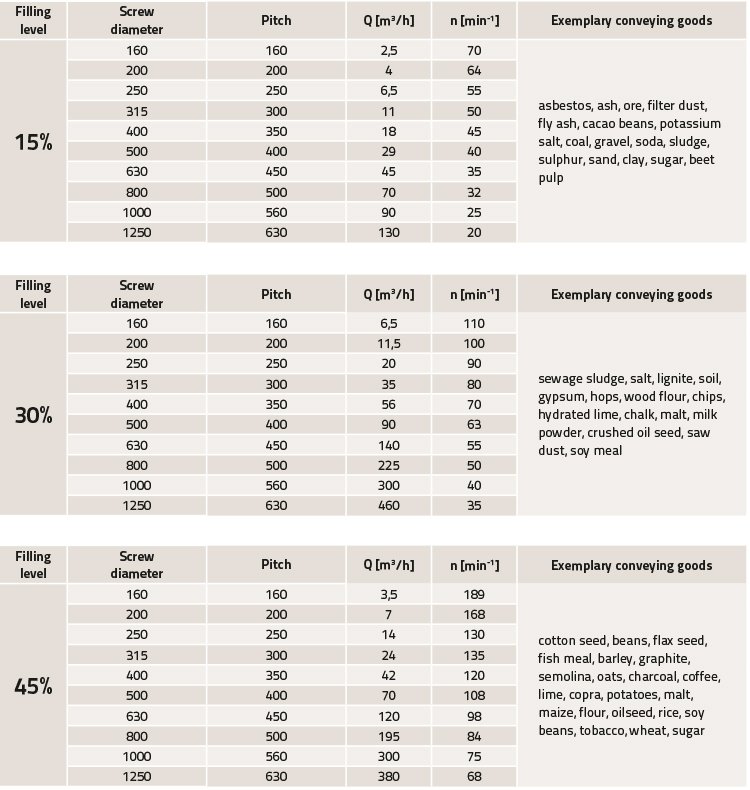

Theoretical conveying capacity in proportion to filling level

Screw conveyor construction modular system

- Driving console:

with shaft-mounted geared motor and torque support, with spear gear motor with coupling, pedestal bearing with gland nut, flange bearings with sealing ring

- End console:

pedestal bearing with gland nut, flange bearings with sealing ring

- Conveyor trough:

tube trough, V-trough, box trough, U-trough

- Inlet:

variable

- Worm shaft:

tubular shaft with blade or paddle, worm shafts without tubular core

- Outlet:

variable